Thank you to everyone who joined in with work week at Swindon Panel last week.

Some great progress was made by the Panel Society and the Great Western Society Civil Engineering (CE) Group.

Uffington Loops 1986 or 2016…..?

Uffington Loops were the only point of refuge between Highworth Junction and Steventon after the line between Challow and Wantage Road was de-quadrupled and Marston Crossing loops were closed in the 1960s.

The loops were removed in the early 1990s when Challow-Wantage was re-quadrupled in response to the increase in coal traffic between Avonmouth and Didcot Power Station.

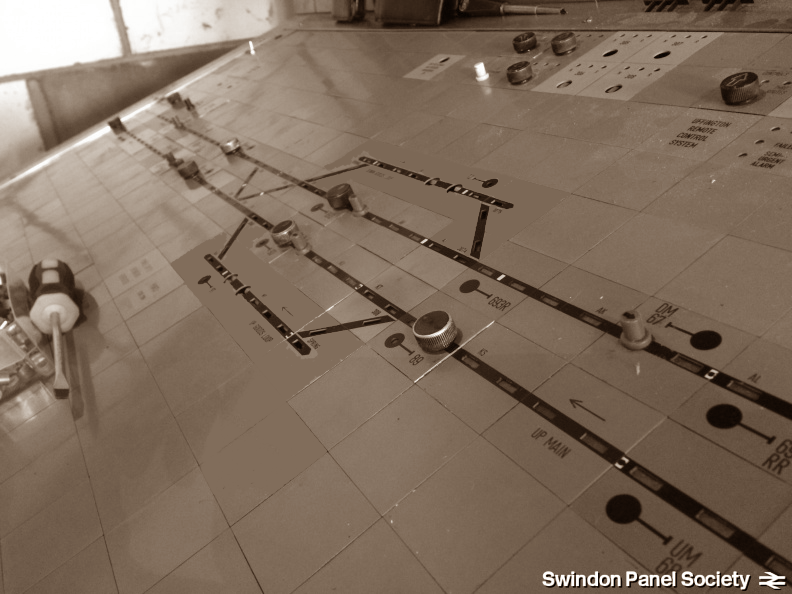

Considerable effort was required to reinstate the loops in the preserved Swindon Panel as the surrounding tiles had been moved around considerably.

The red team installed the new panel top plates that had been delivered from Henry Williams to help up return the panel to its 1980s state. This also required the configuration of numerous mechanisms (the metal housing underneath the tile, below left) and bases (the electrical terminals in the panel, below right) built up from spares.

Several new components were made and configured for the simulator installation, such as this voltmeter and ammeter instrument for the simulator’s three power supplies.

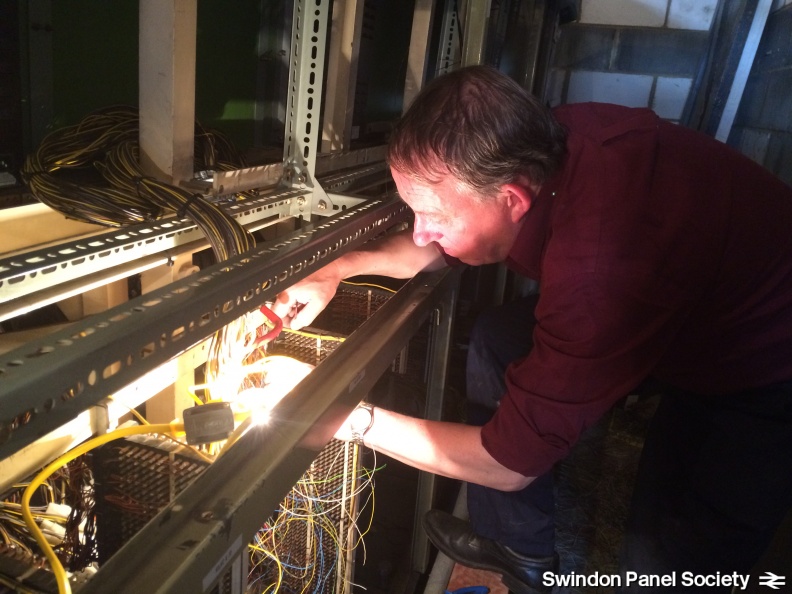

The last of the wiring that linked the tag blocks to the relay room at Swindon has now been removed (hurrah!). There is some further tidying up to do, and then….. yes, for every wire we removed we have to solder a new one back on!

The glazing has started to be installed in the reclaimed cast windows. There are 12 panes required in each of the 4 main windows, plus a couple of smaller ones. Each has to be individually installed and puttied into place.

A considerable construction of ‘Dexion’-style slotted racking has been installed in the back of the panel. This is to support the extensive microelectronic simulator that will be installed in the back of the panel.

The panel simulator power supplies have started to be installed and wired in. Here is the main power area (‘bay 0’). There will be 8 other ‘bays’ of simulator equipment stretching the entire length of the panel.

In addition, the simulator room has started to be built. This is a small room in the Bristol Room where all our computer equipment will live, and the simulator operator will sit (when required).

Also, the GWS S&T Dept, who are the main leaders in the installation of signalling exhibits in the Bristol and Brunel Rooms have started to make great progress in starting to shape the display areas etc in this part of the building.

More photos from 2016 Work Week 1 are available in our Photo Gallery.

2016 Work Week 2….

Just around the corner!

Work Week Part 2 is Saturday 20 to Monday 30 August… and you can be involved!

Work week is a great time for a concerted effort of progress on the panel – it feels really great to be part of the team and see progress being made!

Tasks for Work Week 2 include:

– “The Prod Test” – attaching a prong to each of the tags in the back of the panel and confirming that the correct lamps on the front illuminate in the correct combination. This is important in order to identify any irregularities or inconsistencies in the panel wiring, and also to confirm our alterations have been successful, before they panel is connected to the delicate simulator electronics.

– Panel Domino Construction – Continuing with the task of reconfiguring and compiling new bases and mechanisms that the panel requires to work (second half of the week).

– DIN Rail Installation – The back of the panel is now fitted with racking ready to accept DIN rails. 7 bays of 5 DIN rails are required, which will then require clips attached for 10 PCBs to live on each one. Yes – 350 PCBs! Once the clips are in, it’s time to chase cables from the future position of each PCB to its appropriate tag block.

– Tag Looping Alterations – Some alterations are required to the orange ‘looping’ on the tag blocks. This is because our simulator will be wired slightly differently to how the real interlocking was (but will work in exactly the same way).

– Component packaging and/or soldering – The many thousands of components for the simulator require sorting and packaging up for sending out to the soldering army…… more about that later!

– Window glazing fitting and door frame carpentry – If you fancy something a bit more heavy-duty, the CE group will be continuing their work of installing the windows and doors on the building.

As you can see there is plenty to do, hopefully something for all tastes. The Railway Centre will also be open and is fascinating to look round.

So if you have a spare day or two, come and join us and help bring the completion of the preservation of your favourite panel a little bit closer!

Network Rail employees…. remember, you can get paid by NR for volunteering with Swindon Panel! Read more….